Start a new 2D sketch and select the plane. Now we select “Create” and name the part. Now we are outside of the back and we want to put something protruding out of it. We press “Return” to get out of the part. Now that we have the back we want to create the mounts. We want it to be the thickness of the wood, so we’ll make it. Symmetric, Asymmetric, Direction 1 or Direction 2. It can be extruded in many different ways. We now use the “e” key to extrude the shape. In the video you can see how we can move and constrain the shape. It does not need to be fully constrained. When the shape is green it means it is not fully constrained. We select a rectangle and that will be our “back” for now. When you select that plane you are now “on” that plane. You can pick whatever plane you want from here because it doesn’t matter. We are now faced with a blank screen, so we need to start a 2D sketch. We will then place it somewhere on the screen. We want to select “Create” and name it under “New Component Name”.

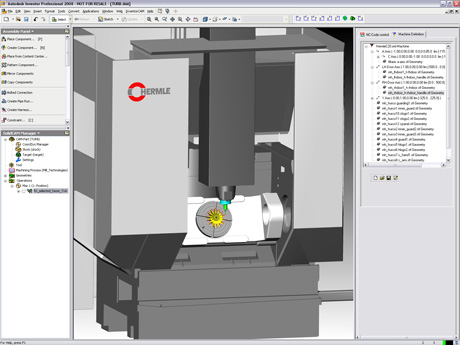

We’re going to make a Z axis assembly for the blueChick to hold a Porter Cable 890 router. These videos can also serve as a good primer if you are deciding to get into using Inventor for your projects. During the Inventor portion of the video series you’ll learn a ton of advanced topics including: using properties from parts of the assembly to provide dimensions for a particular part, or using Excel to provide the dimensions you need so the assembly and parts are fully parametric.

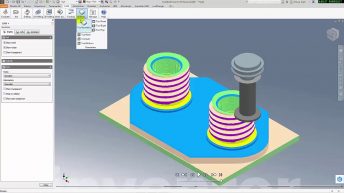

In this video tutorial we will show you how to use Autodesk Inventor to design two parts using a CAM program (CAMBAM) to apply machining operations to create the cutting profiles and drills to fabricate these two parts on the greenBull CNC machine.

0 kommentar(er)

0 kommentar(er)